PRODUCT INFO

Precision cutting capability gives you the ability to deliver custom and short-run items such as labels, T-shirt transfers or package prototypes.

With the Mimaki CJV150 Series printers’ superb quality, color fidelity and flexibility plus cutting capability you’ll go beyond the expected to increase your business and deliver more than your customers can imagine.

Highlights of the Mimaki CJV150 Series Printer

The ability to pre-cut before printing prevents common problems such as film separation and other issues related to post-cutting on thin materials.

Eco Solvent or Dye Sublimation

The CJV150 Series can be configured for either eco solvent printing for sign and graphics applications or for dye-sublimation printing for textile and apparel transfer sublimation applications.

Expanded Eco Solvent Ink Set with Silver

The SS21 eco solvent ink set includes ten colors including Silver, which can be used to create metallic color effects for labels, decals and package prototyping jobs.

Uninterrupted Ink Supply System (UISS)

When printing in CMYK, CJV150 Series printers can be configured with two ink cartridges per color. Utilizing the UISS (Uninterrupted Ink Supply System) when one cartridge is emptied, the printer automatically switches to the full cartridge to deliver continuous imaging.

Precision Ink Drop Placement

Mimaki designed an optimum waveform enabling the print head to jet each ink color at the appropriate jetting angle without losing precise ink droplet circularity.

Anti-Banding Technology

Variable drop printing combined with MAPS3 (Mimaki Advanced Pass System 3) technology ensures precise and accurate print quality throughout the printing process, greatly reducing the appearance of banding and resulting in a smoother image.

Uniform Media Drying

A Mimaki-patented, three-way intelligent heating system results in uniform ink drying across the width of the printer, assuring even image quality.

- Pre-heater: Heats media to the optimum temperature before printing.

- Print heater: Dries ink after it lands on media before it bleeds, improving color development.

- Post-heater: Enhances ink drying and achieves stable take-up.

- Top blower: Air blower supports drying of ink.

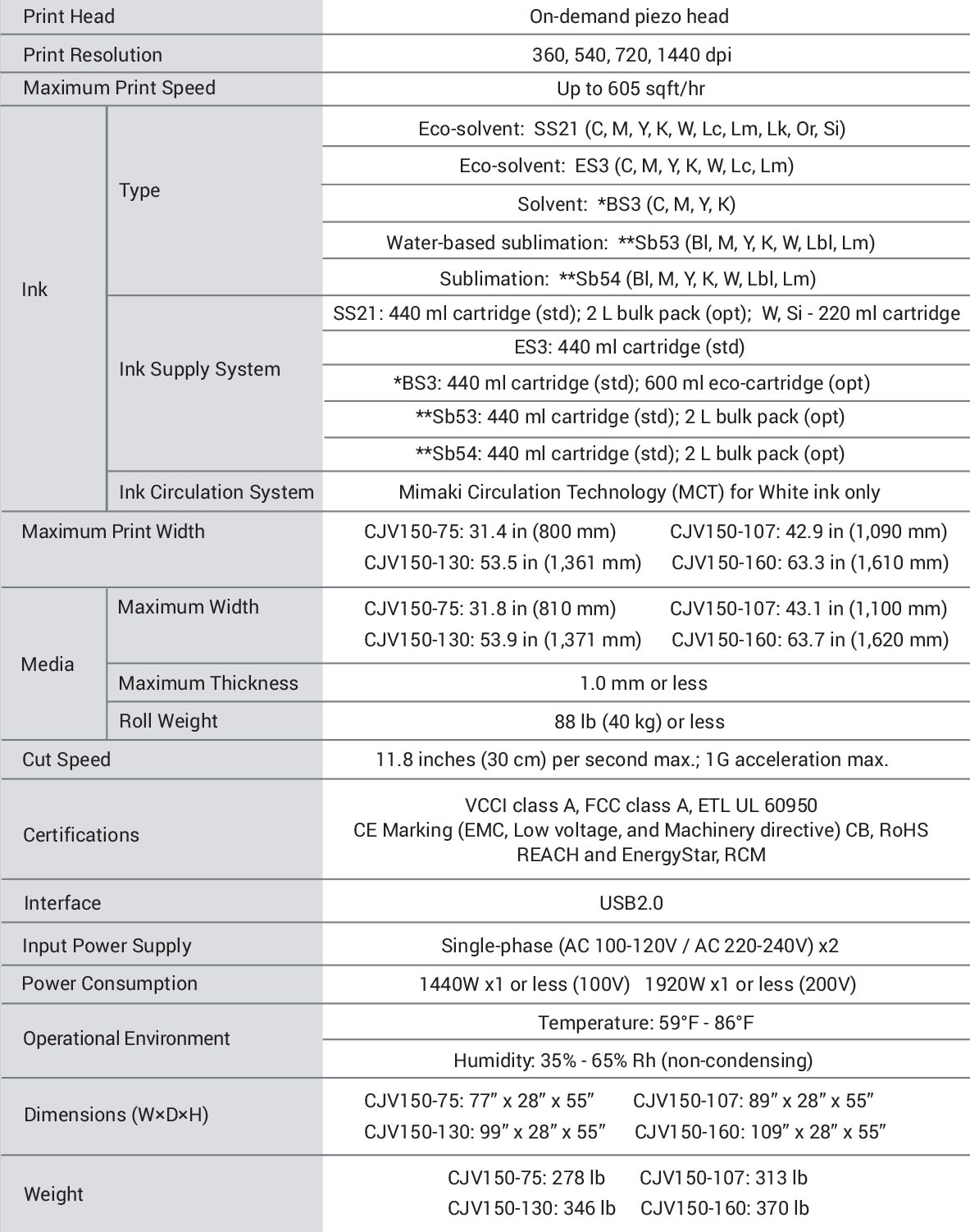

SPECIFICATIONS

6761 N.E. 4th Ave. Miami, Florida 33138 | Toll Free: (800) 991-6366 | Tel: (305) 628-8345 | Email: info@dgs-usa.com / sales@dgs-usa.com

Copyright © 2019 Digital Graphic Systems. All rights reserved.